Description

The rectangular bellows, however, are also suitable for the protection of components with polar movement (elbow) since they can tolerate lateral bending that other geometries do not allow.

They are therefore used in devices such as mechanical arms, robotic arms, electrical cable passage channels, and support and rotation systems for panels or push buttons.

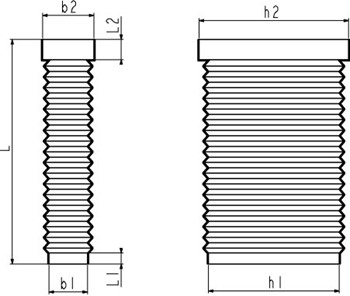

| Code | B1 (mm) |

H1 (mm) |

L1 (mm) |

B2 (mm) |

H2 (mm) |

L2 (mm) |

Lenght MAX (mm) |

Lenght CLOSED (mm) |

|---|---|---|---|---|---|---|---|---|

| SOF RET P | 33 | 55 | 10 | 36 | 57 | 10 | 220 | 105 |

| SOF RET M | 35 | 114 | 9 | 35 | 114 | 9 | 240 | 180 |

| SOF RET G | 46 | 175 | 0 | 60 | 195 | 10 | 380 | 70 |

| SOF RET 300 | 280 | 300 | 20 | 305 | 300 | 15 | 400 | 180 |

| SOF RET 370×370 | 368 | 368 | 15 | 368 | 368 | 15 | 250 | 170 |