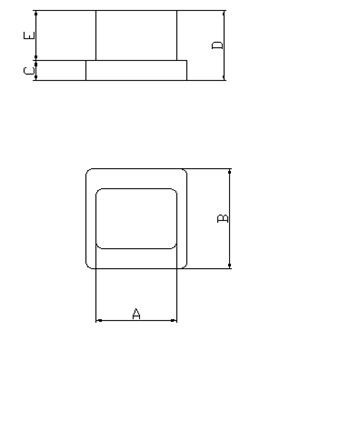

Description

| Code | A (mm) | B (mm) | Height E (mm) | Tot height (D) (mm) | Head thickness (C) (mm) |

| TAP 20 | 18 | 21 | 15 | 20 | 5 |

| TAP 22 | 22 | 26 | 19 | 23,5 | 4,5 |

| TAP 28 | 28 | 36 | 21 | 31 | 10 |

| TAP 32 | 32 | 40 | 22 | 31 | 9 |

| TAP 38 | 38 | 46 | 21,5 | 31 | 9,5 |

| TAP 43.5 | 43,5 | 50,75 | 21,5 | 30 | 8 |

| ETGQ94/94 | 94 | 94 | 20 | 25 | 5 |