Description

Description

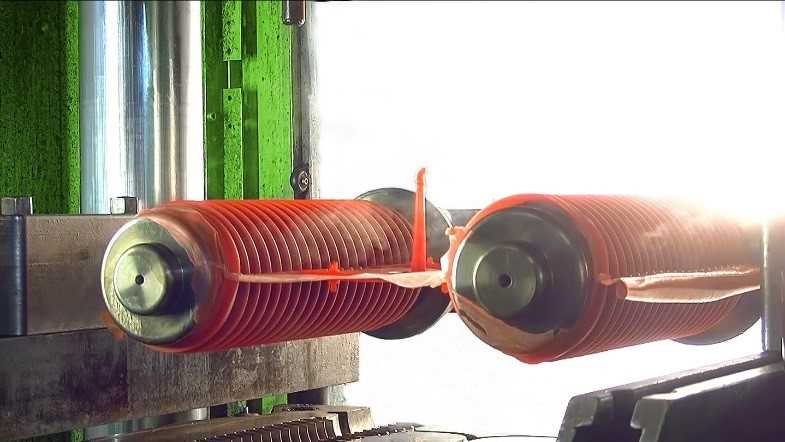

The modular bellows consists of 3 main components: Bellows, collar, and joint.

The collars and joints are assembled with the bellows by interlocking the ends. The collars are the two end sections of the bellows.

By drilling a hole of the correct dimensions, you can obtain the perfect grip on the flange and ensure the seal.

The optional joint allows the connection of more bellows together so as to obtain any length.

Available in various models and dimensions, the modular bellow is the ideal solution. Its appearance is perfect for the application and, at the same time, it ensures complete protection for any mechanical component.

Watch the video below to see how easy it is to use the modular bellow