Description

Suggested materials:

SBR Styrene-butadiene rubber

NBR Nitrile rubber

(Standard = SBR)

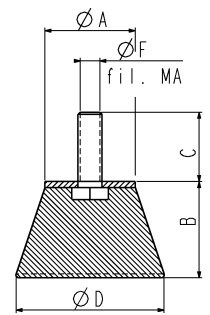

| Code | Ø A (mm) | Ø D (mm) | B (mm) | Screw F (mm) | C (mm) | Max Compression Load (Kg) |

| PIE 30/13PM8 | 25 | 30 | 13 | 8MA maschio | 19 | 45 |

| PIE 30/26PM6 | 26 | 30 | 22 | 6MA maschio | 10 | 48 |

| PIE 34/16PM6 | 28 | 34 | 16 | 6MA maschio | 10 | 50 |

| PIE 40/20PM8 | 29 | 40 | 20 | 8MA maschio | 18 | 70 |

| PIE 37X50PM8 | 38,5 | 50 | 36 | 8MA maschio | 18 | 90 |

| PIE 50/20PM10 | 46 | 60 | 20,5 | 10MA maschio | 27 | 150 |