Description

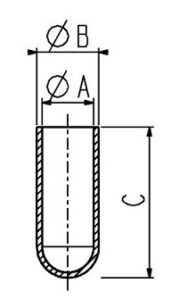

| Code | For screw | Ø A (mm) | Ø B (mm) | Lenght C (mm) |

| EPS03 | M 3 | 3 | 5,5 | 20 |

| EPS04 | M 4 | 4 | 6,6 | 20 |

| EPS05 | M 5 | 5 | 7,7 | 21 |

| EPS5.80 | M 6 | 5,8 | 9,6 | 10 |

| EPS06 | M 6 | 6 | 8,8 | 21 |

| EPS10 | M 10 | 10 | 12,8 | 33 |

| EPS12 | M 12 | 12 | 14,4 | 35 |

| EPS12/52 | M 12 | 12 | 15 | 52 |

| EPS12/80 | M 12 | 12 | 15 | 87 |

| EPS14 | M 14 | 14 | 16 | 35 |

| EPS16 | M 16 | 16 | 19 | 35 |

| EPS17/80 | M 17 | 17 | 20 | 80 |

| EPS18 | M 18 | 18 | 21 | 35 |

| EPS18/80 | M 18 | 18 | 21 | 80 |

| EPS20 | M 20 | 20 | 24 | 35 |

| EPS25 | M 25 | 25 | 35 | 30 |

| EPS25/1 | M 25 | 25 | 35 | 55 |

| EPS30 | M 30 | 30 | 38 | 65 |

| EPS40 | M 40 | 40 | 47 | 46 |

| EPS46 | M 46 | 46 | 52 | 46 |

| EPS55 | M 55 | 55 | 68 | 18 |

| EPS70 | M 70 | 70 | 74 | 65 |