Description

Our standard product range is composed of bellows with a simple design. Sophisticated designs featuring protection systems as well as special designs for JOYSTICKS and hydraulic distributors are also available. Our engineers are standing by to perfectly match your customized devices.

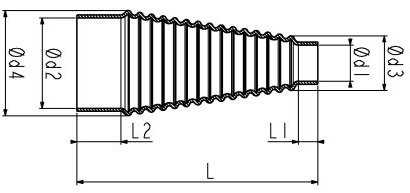

| Code | Ø d1 (mm) | L1 (mm) | Ø d2 (mm) | L2 (mm) | L (mm) | Ø d3 (mm) | Ø d4 (mm) |

| SOF CON 2.5X25 | 2,5 | 2 | 22 | 2 | 25 | 25 | 33 |

| SOF CON 4.5X28 | 4,5 | 2 | 19 | 5 | 28 | 14 | 25 |

| SOF CON 06X32 | 6 | 1 | 18 | 4 | 32 | 18 | 24 |

| SOF CON 6.5X34 | 6,5 | 2,5 | 27,5 | 2,4 | 34 | 32 | 38 |

| SOF CON 6.5X32 | 6,5 | 2 | 28 | 5 | 32 | 20 | 34 |

| SOF 028 | 8 | 10 | 47 | 12 | 162 | 32 | 61 |

| SOF CON 8X50 | 8 | 4 | 27 | 10 | 50 | 27 | 32 |

| SOF CON 8.5X45 | 8,5 | 2 | 36 | 5 | 45 | 25 | 43 |

| SOF CON 09×50 | 9 | 5 | 60 | 10 | 50 | 20 | 30 |

| SOF 30X43 | 9,5 | 11 | 30 | 17 | 43 | 28 | 35 |

| CUF 10 | 10 | 3 | 38 | 9 | 38 | 38 | 46,5 |

| SOF CON 10X85 | 10 | 2,5 | 107 | 3,5 | 85 | 50 | 110 |

| CUF VAL P | 11 | 12 | 65 | 0 | 55 | 43 | 82 |

| GAL SOF 27610 | 12 | 7 | 22 | 7 | 24 | 31 | 36 |

| SOF CON 12X42.5 | 12 | 3 | 36 | 8 | 42,5 | 25 | 46 |

| SOF CON 12X130 | 12 | 10 | 70 | 16 | 130 | 40 | 75 |

| SOF CON 14X29 | 14 | 10 | 25 | 9,5 | 29 | 25 | 30 |

| CUF VAL G | 14 | 14 | 84 | 15 | 78 | 61 | 102 |

| SOF 14X60 | 14 | 12 | 48 | 5 | 60 | 35 | 66 |

| SOF CON 14.3X75 | 14.3 | 0 | 90 | 0 | 75 | 34 | 88 |

| SOF CON 15X84 | 15 | 12 | 62 | 4 | 84 | 40 | 76 |

| SOF CON 16X105 | 16 | 11 | 40 | 16 | 105 | 24 | 50 |

| SOF CON 18X44 | 18 | 4 | 44 | 2 | 44 | 48 | 48 |

| SOF CON 18X90 | 18 | 8 | 70 | 10 | 90 | 40 | 100 |

| SOF CON 20X33.5 | 20 | 2 | 37 | 3 | 33,5 | 38 | 42 |

| SOF CON 20X33.5X42.5 | 20 | 3 | 42,5 | 6 | 33,5 | 30 | 53 |

| SOF CON 20X165 | 20 | 20 | 87 | 18 | 165 | 65 | 135 |

| SOF CON 23X35 | 23 | 3 | 50 | 2 | 35 | 25 | 62 |

| SOF CON 23X170 | 23 | 15 | 90 | 12 | 180 | 62 | 116 |

| SOF CON 23.5X43 | 23,5 | 6 | 58 | 7,5 | 43 | 63 | 74 |

| SOF CON 26X90 | 26 | 8 | 70 | 10 | 90 | 55 | 100 |

| SOF CON 27X208 | 27 | 15 | 56 | 5 | 208 | 63 | 80 |

| SOF CON 28X46 | 28 | 4 | 70 | 12 | 46 | 32 | 74 |

| SOF CON 28X50 | 28 | 5 | 50 | 8 | 50 | 50 | 65 |

| SOF CON 29X140 | 29 | 20 | 73 | 1 | 140 | 70 | 93 |

| SOF CON 32X35 | 32 | 12 | 54 | 1 | 35 | 60 | 95 |

| SOF CON 35.5X54 | 35,5 | 5 | 58 | 5 | 54 | 62,5 | 85,5 |

| SOF 140X35 | 40 | 30 | 110 | 38 | 160 | 71 | 104 |

| SOF CON 45X55 | 45 | 6 | 108 | 7,5 | 55 | 80 | 100 |

| SOF CON 53X47 | 53 | 10 | 67 | 5 | 47 | 65 | 80 |

| SOF CON 60X170 | 60 | 10 | 130 | 10 | 170 | 80 | 130 |